Reducers are one of the many types of fitting that can be used to control the flow within a piping system. In a piping system, there are two major types of reducers: concentric reducer and eccentric reducer. This article compares the two types of reducers:Concentric VS Eccentric Reducer

It is mainly used in pipeline systems to enable fluids to transition smoothly between pipes of different diameters. It is widely used in pipeline projects in many industries such as petrochemicals, electric power, and building water supply and drainage.

Types of ASME B16.9 Reducers

●Concentric Reducer

●Eccentric Reducer

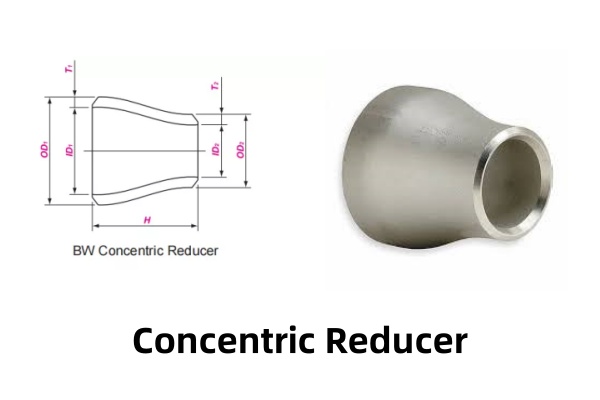

What is a Concentric Reducer?

A concentric reducer is a pipe fitting that is in the shape of a cone. In this cone structure, the centers of the large-end cross-section circle and the small-end cross-section circle are located on the same central axis. This is an important feature that distinguishes it from an eccentric reducer.

The design of a concentric reducer ensures that the smaller pipe end aligns symmetrically with the larger pipe’s center line, providing a smooth transition. This uniformity helps maintain constant fluid flow, minimizing turbulence or disruptions in the system.

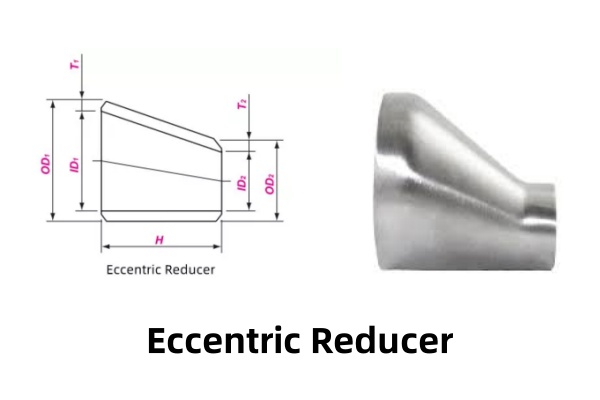

What is a Eccentric Reducer?

The eccentric reducer is a butt weld pipe fitting used to connect two pipes of different diameters whose centers are not on the same straight line. Since the centers are not coincident, the eccentric reducer has the function of changing the direction of the pipe, balancing the pipe deviation and reducing stress concentration.

Unlike a concentric reducer, which resembles a cone, eccentric reducers have an edge that is parallel to the connecting pipe, referred to as the flat side. This parallel edge results in the two pipes having offset center lines. Because eccentric reducers are asymmetrical, they create asymmetrical flow conditions; flow is faster along the angled side, resulting in increased pressure.

Concentric VS Eccentric Reducer

Features of Concentric Reducers:

●Concentric reducers help to convey slurries and abrasive fluids and are useful to use in operations where corrosion is present.

●These concentric reducers are beneficial to use where different ratings and wear protection are required in conveying between flanges or pipes.

●Concentric reducers lower the diameter of the pipe in the middle.

●A concentric reducer enhances fluid flow while reducing the diameter and has no effect on the fluid flow condition. As a result, concentric reducers are utilized for gas and vertical flow liquid pipelines.

Features of Eccentric Reducers:

●When the pipes must keep the same top or bottom level, eccentric reducers are utilized.

●Eccentric reducers are useful for exhaust or liquid discharge since one side of the eccentric reducer is flat, making start-up and maintenance easier. As a result, eccentric reducers are commonly utilized in horizontal liquid pipelines.

●Where pipe is positioned vertically and pumps discharge, concentric reducers are used.

Applications of Concentric and Eccentric Reducers

Concentric Reducers

In chemical production, the transportation of many raw materials requires precise control of flow rate and flow direction. Concentric reducers can ensure that the fluid flows evenly and symmetrically at the point where the pipe diameter changes. In the long-distance oil transportation pipeline system, concentric reducers help reduce energy loss. The symmetrical structure of the concentric reducer makes the increase in flow rate and the decrease in pressure more uniform when the oil transitions from a large-diameter pipeline to a small-diameter pipeline, reducing the generation of turbulence.

Eccentric Reducer

Eccentric reducers are the first choice for horizontal pipelines. Their ability to prevent the formation of air or cavitation is essential for systems that transport dense or mixed fluids. In some chemical process pipelines, there may be gas-liquid two-phase flow or liquid accumulation. The eccentric reducer can guide the accumulated liquid to a specific collection location through a reasonable installation direction.

Conclusion

Concentric and eccentric reducers play crucial roles in the functionality and efficiency of pipeline systems in various industries. These pipe fittings optimize fluid flow by regulating pressure, reducing flow rates, and preventing clogs and blockages. The advantages of these reducers are their durability, cost-effectiveness, long-lasting performance, and easy maintenance. It is essential to understand the functions and uses of reducers to ensure the efficiency and longevity of pipeline systems.

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....